19/01/2026

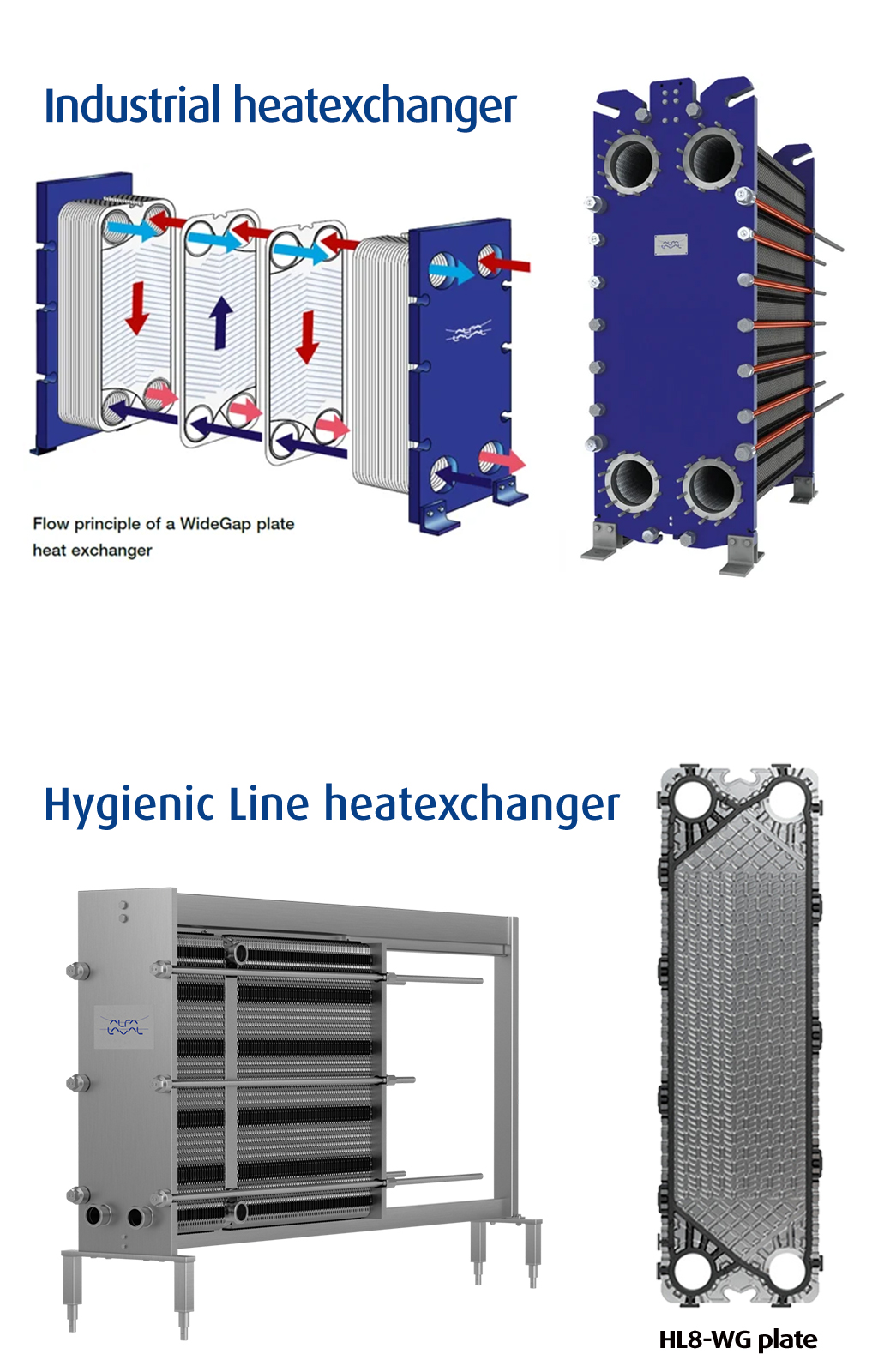

WideGap: more output, less downtime

Working with fiber-rich or viscous media? The Alfa Laval WideGap, available via SKS, is purpose-built for liquids containing fibers, coarse particles or high viscosity. Thanks to wide channel openings, a SmoothPort™ inlet and an optimized plate pattern, WideGap delivers high heat transfer with minimal clogging risk, compact, energy-efficient and easy to clean (CIP).

The technology proves itself across diverse processes: from food, dairy and beverages to biotech, chemicals and (waste)water. Flexible configurations (wide-wide or wide-narrow) enable heating, cooling or combined duties with low pressure drop and extended maintenance intervals, boosting uptime and lowering total cost of ownership.

Why WideGap?

- High energy efficiency

- Free flow without build-up

- Fast, easy cleaning (less downtime)

- Lower maintenance and longer intervals

Typical applications: Fruit pulp, sauces, syrups, starch, fiber/particle-rich waste streams and high-viscosity liquids.

In practice: Dolomiti Fruits replaced tubular exchangers with WideGap units and achieved up to 45% less steam consumption and 15% energy savings, plus better heat recovery and reduced pump load.