Are you active in the food, pharmaceutical, or chemical industry? Then you know how crucial reliable and efficient heat exchangers are. The Alfa Laval WideGap, available through SKS, is specifically designed for liquids containing fibres, coarse particles, or with high viscosity. Ideal for applications where standard heat exchangers fall short.

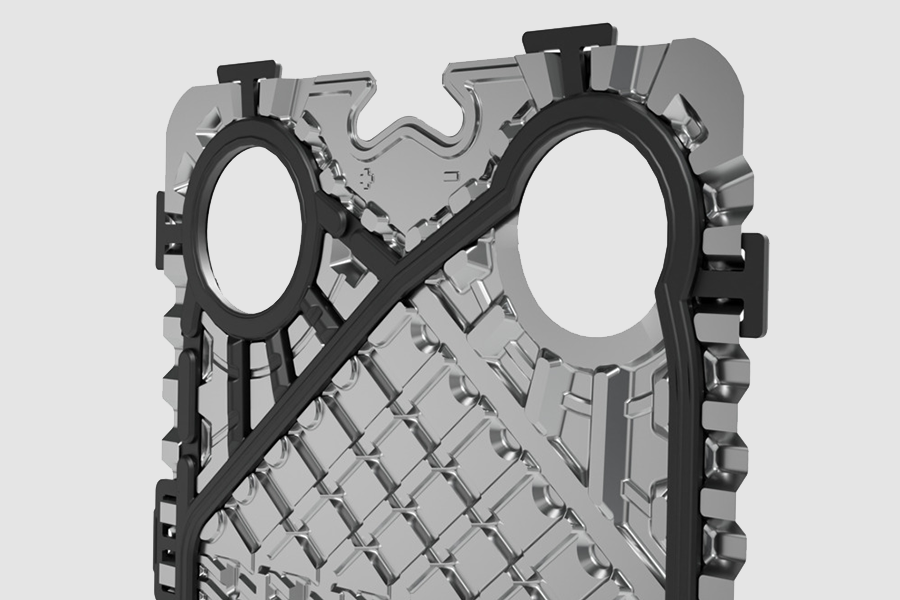

Thanks to its innovative design with wide channel openings, smooth port design and optimized plate pattern, the WideGap ensures high heat transfer efficiency and minimal clogging. This makes it especially suitable for processes where food production, chemical treatment, and water management are key.

Where is the Alfa Laval WideGap used?

This heat exchanger is highly versatile and used in biotech, pharmaceutical, food, sugar and bioethanol production, pulp and paper, petrochemicals, heat recovery, and wastewater treatment. Its flexible configuration, wide-wide or wide-narrow channels, makes it suitable for heating, cooling or mixed duties with variable flows.

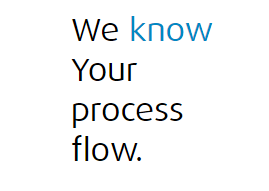

How the WideGap works

The heat exchanger consists of corrugated plates mounted between a frame and pressure plates that maintain design pressure.

Fluids typically flow in opposite directions through the unit to ensure maximum thermal performance at small temperature differences.

Thanks to the smart plate pattern and pressing depth, even challenging fluids can circulate without any effort.

Our sales engineers are happy to help you select the ideal configuration for your application.

Configurations

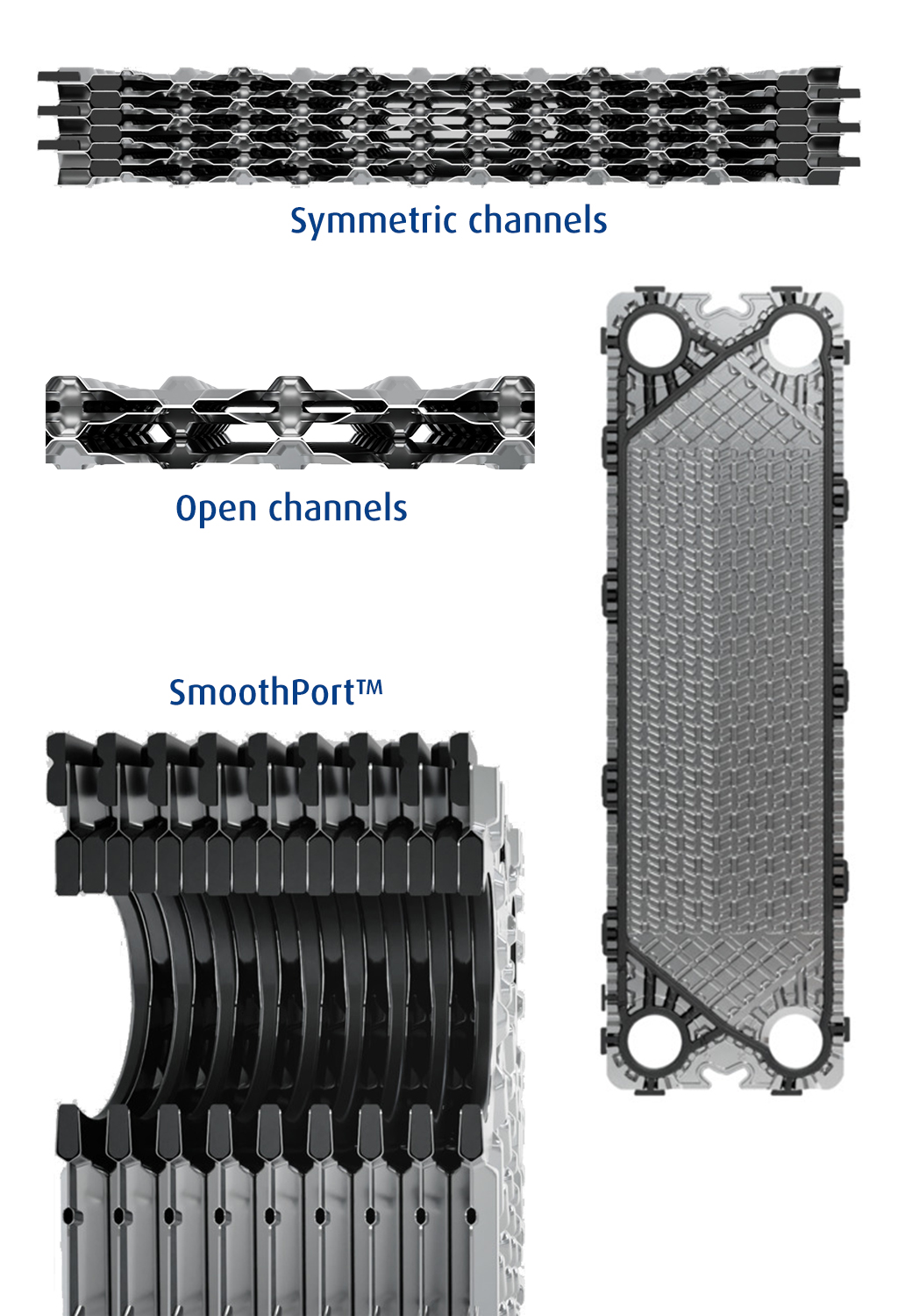

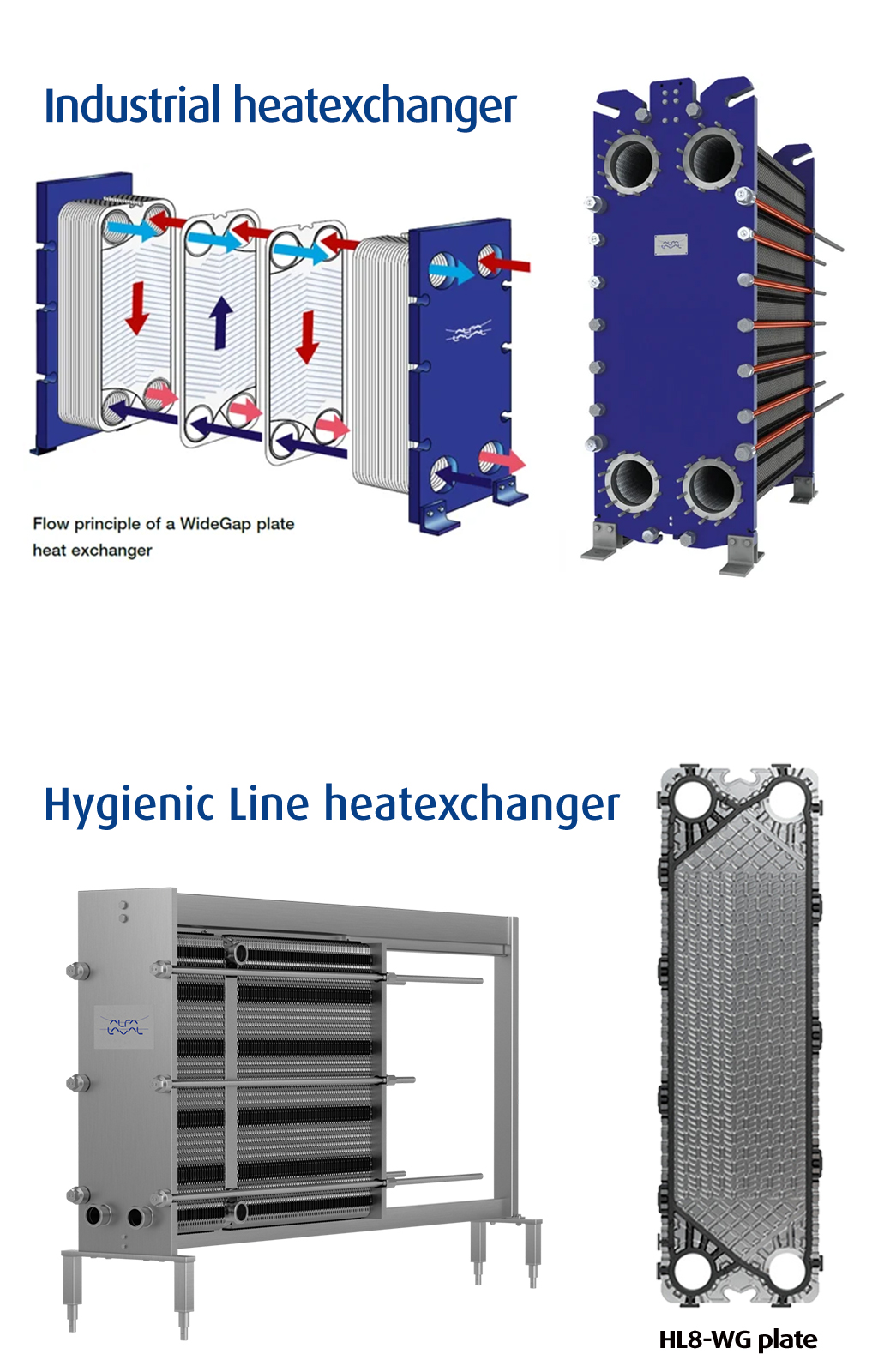

The WideGap plate heat exchanger can be configured in various ways.

The channels can have a ‘wide/wide’ or ‘wide/narrow’ opening, with different gap sizes between the channels.

WideGap heat exchangers are typically configured as multi-pass units to ensure sufficient turbulence.

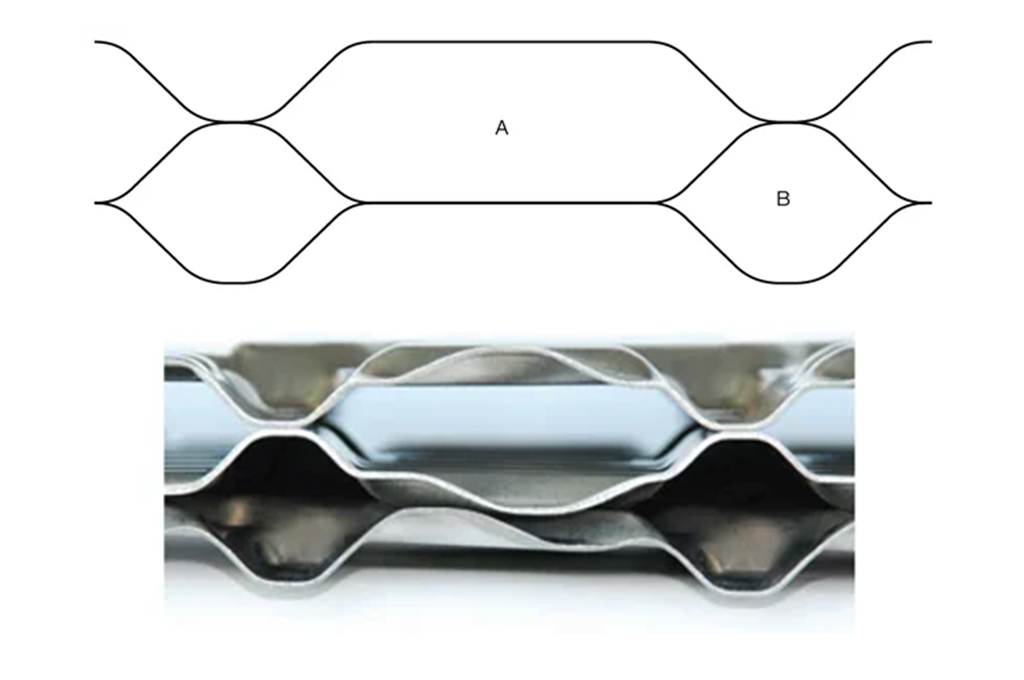

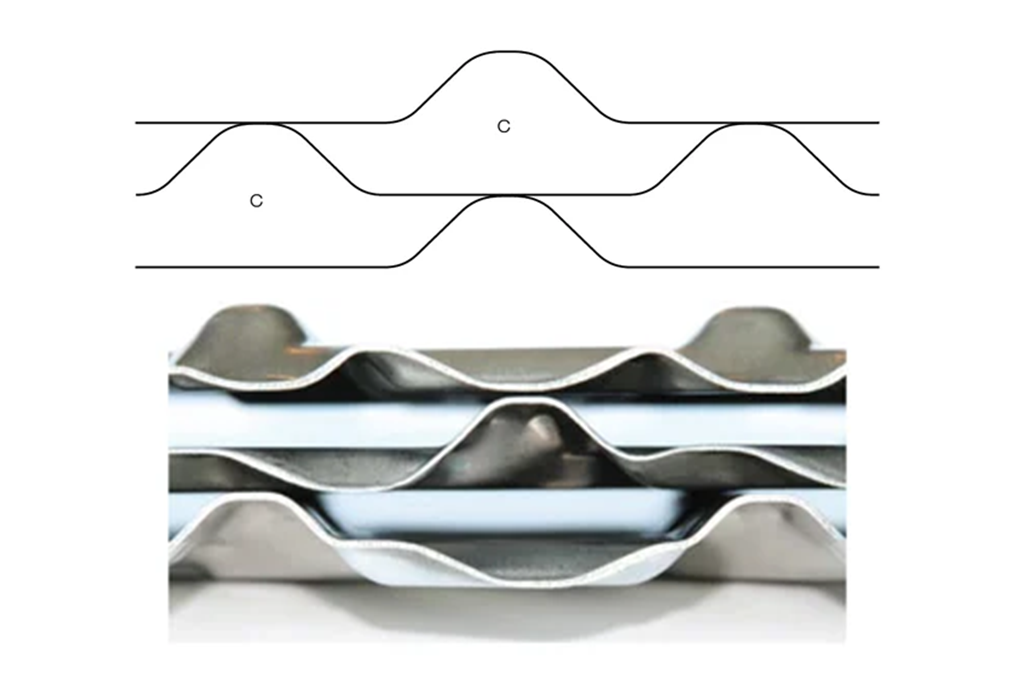

The illustrations below show cross-sections of the two different configurations.

Single-Side WideGap

An extra wide channel for fibrous/contaminated fluid (A) and a channel for non-fibrous fluid (B).

Double-Side WideGap

Two wide channels for fibrous / contaminated fluids (C).

SKS, your partner in Heat Exchanger Solutions

SKS supports customers across the Netherlands, Belgium, Luxembourg and Germany with complete heat exchanger expertise.

From design support to troubleshooting, optimisation and training, we help ensure reliable performance in every application.