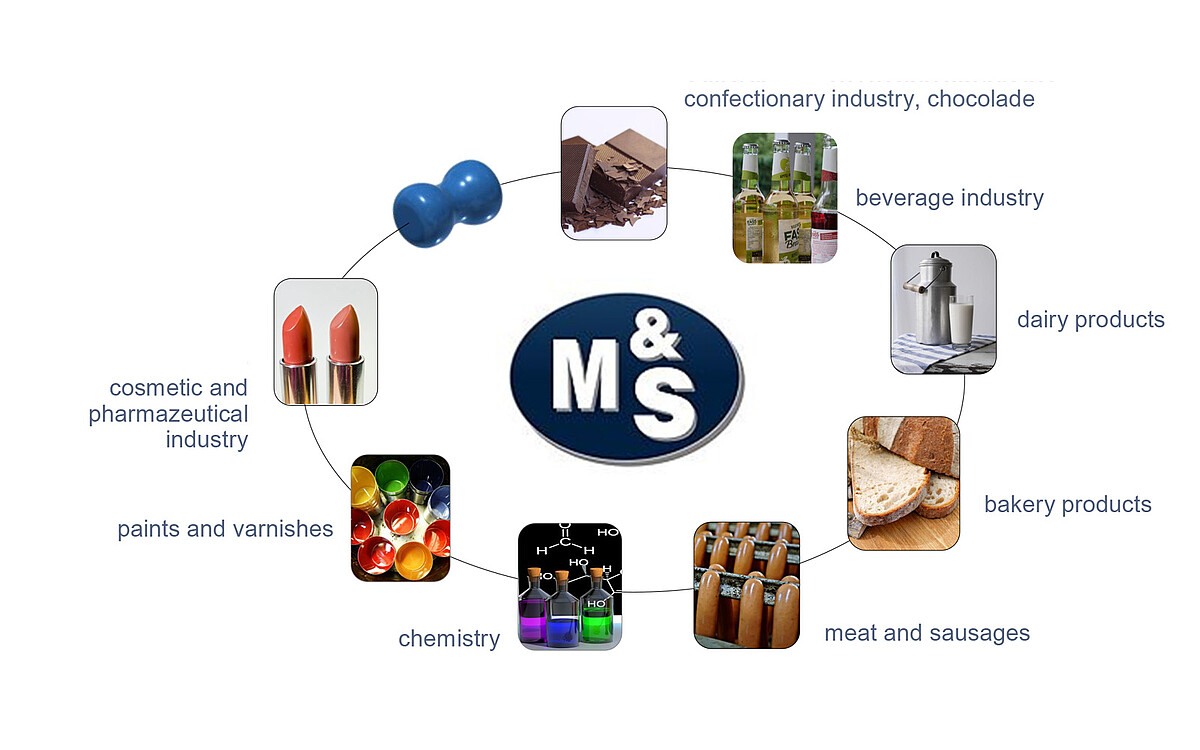

M&S systems

Get the most out of your production Process

Looking to increase yield per batch, reduce waste and save on cleaning costs? Then choose the advanced pigging system from M&S. This smart technology ensures maximum product recovery from your process pipelines. No residue, no waste, and a fast return on investment. Efficient, sustainable and profitable.

- Full exploitation of the production without any losses

- Small batches without losses

- Quick product change

- No mixing phases

- Less numbers of pipelines (reduced investment costs)

- Avoiding of sediments in pipeline

- Up to 90% less use of cleanising media

- Longer cleaning agent service life

- Lower degree of waste water contamination

- Increase in efficacy

- Short payback periods

BASE//LINE M&S Product Recovery System

Single way and shuttle systems for simple application such as meat, confectionery or baked goods, drink and tobacco, etc.

PRO//LINE

Single way and shuttle systems as CIP/SIP capable models for foodstuffs such as dough, meat emulsion, dairy products, cosmetics and special fibrous or bulky products.

HY//LINE

As inline station for single way and shuttle systems in CIP/SIP execution, pig permanent in product flow, for beverages, foodstuffs and cosmetics.

Pigging Stations and Components:

- Sizes DN 25 to DN 150

- Materials AISI 316L, further materials upon request

- VMQ (silicone) seals, EPDM, HNBR and FKM(all FDA conform)

- VMQ (silicone) pigs (FDA conform) with 2 encapsuled high-performance magnets

- Stations operated manually, pneumatic or driven by electric motors

- Stations in CIP/SIP execution

- Complete prefabricated and pretested units

|

SKS: Practical advice with measurable results

A successful project at SKS always starts with listening. We take the time to understand your process and analyse, together with you, where optimisation is possible. Based on your goals, we develop a pigging system that not only fits seamlessly into your production environment but also directly contributes to improved efficiency.

You will receive a clear calculation from us, showing the potential savings and payback period. This way, you can immediately see the return on your investment. We then translate our advice into a concrete design, complete with component selection and technical drawings. Only when every detail is right, do we start with production and delivery.

By choosing SKS, you choose result-oriented advice, backed by expertise and a vision for the future. We think beyond technology. We think in terms of return.

We like to think along with you!Would you like more information or advice about Pigging Recovery Systems? Please complete the online form for a consultation.  |