Logstor systems

Applying the Logstor Pre-insulated tubes SafePipe

- Combines the key benefits from two technologies

- Enables you to detect and monitor leaks before a major damage occurs

- Prevents small leaks developing into major spills

- Ensures that sensor cables are easy to access, maintain and upgrade

- You can use identical inventory and equipment for installations above and below ground

- Easy to install, saving time, manpower and money

Best of two worlds

Logstor Pre-insulated tubes SafePipes makes it possible to benefit from the combined technology, insight and experience available from the best suppliers in two different fields. TraceTek sensor cables and Logstor pipe systems. Together, they provide a supremely reliable, easy-to install, integrated solution for detecting leakages and preventing spills of all kinds from chemical and petrochemical pipe systems.

Where to use

Logstor SafePipes are ideal for transporting:

- Petrol/gasoline, diesel, jet, fuel, crude oil, lube oil and other hydrocarbon-based liquids

- Organic solvents

- Strong acids and bases and other hazardous fluids that contains water

- Contaminated water and polluting liquids in general in a safe, effectively monitored way that makes sure any spills are kept securely within the pipe

Quality-managed production

Logstor proactively addresses both quality and environmental concerns from component manufacture to finished installation. ISO 9001 and ISO 14001 standards are basis for the manufacture of all Logstor pipes and components.

Applying the Logstor Pre-Insulated Pipes for High Temperatures

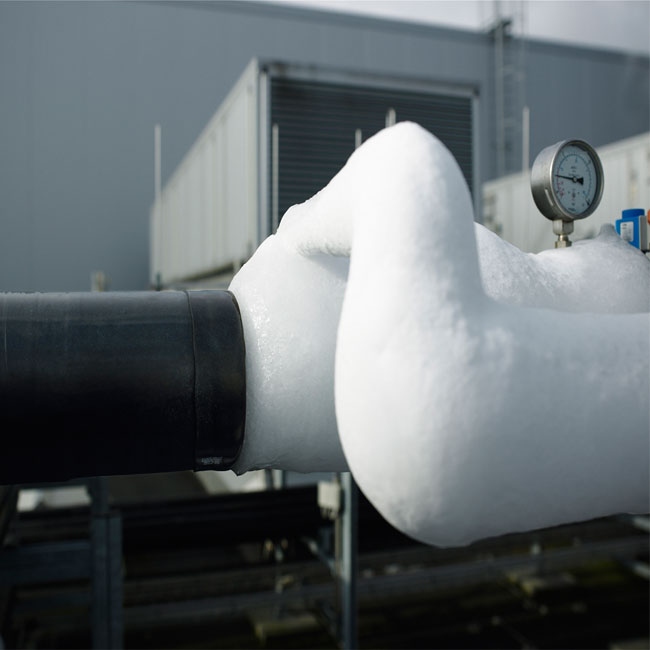

A Logstor pre-insulated pipe normally consists of three parts:

- Carrier pipe: At the center is the carrier pipe, typically a steel pipe of boiler tube quality.

- Insulation: Then comes an insulation layer, which in the case of the high temperature system, consisting of two parts - an inner layer of miniral wool and an outer layer of polyurethane foam (PUR). The mineral wool is intended to protect the PUR insulation against temperatures above 140°C.

- Jacket: On the outside is a protective jacket of polyethylene (PE) that ensures (once joined accoring to Logstor standards) that the moisture can not penetrate the insulation thereby giving a 100% waterproof standard.

High temperature system freely suspended above ground

The freely suspended system functions as a bonded system (i.e. the jacket and carrier pipe expand at the same rate). Supports may be placed directly onto the jacket. Expansion is normally absorbed by bends and expansion joints.

High temperature system for ground burial (HT3)

The buried system functions as a sliding system, i.e. the carrier pipe expands within the insulation without the jacket moving in the ground. Expansion is absorbed within the system by axial compensators or expansion bends.

The two standard insulation series are Series 210 for operating temperatures from 140°C to 210°C and Series 250 for operating temperatures from 140°C to 250°C.

Applying the Logstor for Low and Normal Temperatures

The advantages of the Logstor pre-insulated tubes and our experience and knowledge of process tubes are the best base of your process tubes. The possibilities are limitless within a range from -200 °C up to +350 °C. Especially in tube bridges you can reduce costs according to the investment costs, installation time but mainly the energy costs.

The Mix of 4 Variable Components

- Transport tube: all materials with a diameter up to 800mm

- Isolation: Customized materials based on the temperature of the application

- Jacket: Choice between five robust sorts of materials

- Options: Divers options possible such as leak tracing, leak detection and many more

The combination of the chosen variables is the optimal configuration for your application. The choice depends on the technical and economical input.

Logstor features

- 100% waterproof

- High mechanical resistance

- Effective corrosion protection of the tube

- Resistant against chemical products and UV

- Tracing of the tube is possible

- Sandwich system

- Easy installation of the products

Logstor advantages

- Well cleanable

- Constant isolation during the lifetime

- Quick payback time

- No source of infection

- Less loss of energy

- Low maintenance costs

Customised delivery

Every application is different. That is why the isolation material (based on the temperature and the needed result) is calculated regarding to the size and composition of the isolation material. This can be adapted to your specific needs. The system has some little restrictions but they minor to the enormous advantages. Besides the possibility of the standard tube components, S.K.S. can also isolate the short tube installations, skids-fittings or machine parts. We can even produce these products for you if we get a drawing for it.

| Articlenr. | Description | Stock |

|---|---|---|

|

P01110902

|

Tube Insulation per mtr. HDPE black

PUR Serie 1; Ø90mm

for tube 22-27mm

|

|