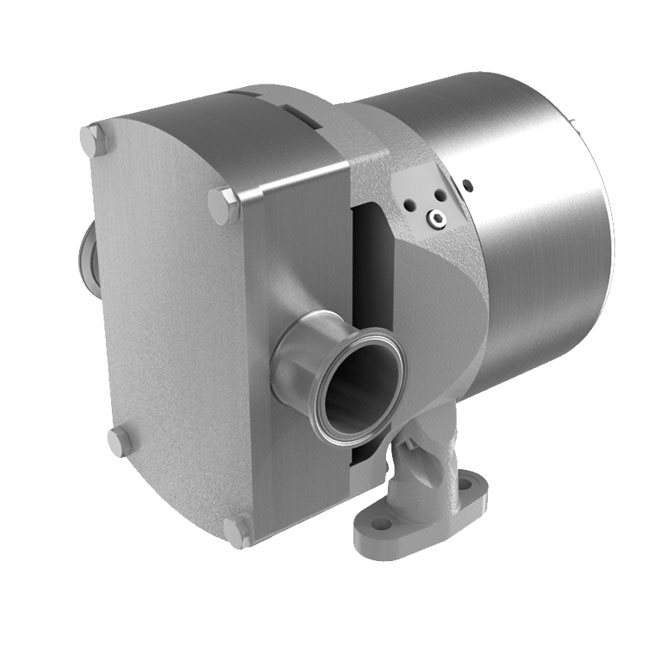

Alfa Laval OptiLobe

Applying the Alfa Laval Rotary Lobe Pump OptiLobe

Suitable for low, medium and high-viscosity media, the Alfa Laval rotary lobe pumps are the fulfillment of more than 50 years of commitment to rotary lobe pump technology. Their gentle pumping action and reliable performance are the result of continuous development, which is based upon years of experience and carried out at our advanced production and R&D facilities. The Alfa Laval rotary lobe pump portfolio comprises three ranges: SX, SRU and OptiLobe. Each of these is robustly constructed and offers Alfa Laval’s high standards of quality and reliability, and each is positioned for a different type of demand. Collectively, they provide operating economy and high flexibility of use.

Gentle, hygienic design

With their high-precision rotors and low-shear operation, the rotary lobe pumps ensure the gentle movement of delicate products. The pumps offer a number of features that maximize cleanability and their construction provides compliance with the world’s leading hygienic standards.

Modular pump design

The rotary lobe pumps feature a modular construction. This design feature increases flexibility and reduces spare parts inventory.

Universal mounting

To allow high flexibility when fitting the pump into a production line, all of our rotary lobe pumps can be mounted in either a vertical or horizontal port position (with the exception of the larger SX models).

Improved drainability

All of our rotary lobe pumps can be drained easily when mounted in vertical port position. In the case of our OptiLobe and SX pumps, cusps are retained in vertical configurations for greater efficiency.

Easy seal retrofit

The seals of the rotary lobe pumps are designed for quick and simple up-grading. The broad range of seals includes many seal types and configurations, which can be tailored to your need and application.

Robust gearbox construction

The rotary lobe pumps are fitted with a robust gearbox incorporating heavy-duty taper roller bearings and torque locking assemblies that allow for easy maintenance and high reliability. The pump rotors are driven by a high-precision involute spline drive.

CIP and SIP

The rotary lobe pumps are suitable for use in both Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP) applications.

Standards and approvals

All of the rotary lobe pumps are compliant with the EHEDG, 3A and FDA hygienic standards. In addition, the SX and SRU pumps have ATEX approval for use in explosive environments.

Alfa Laval Rotary lobe pump OptiLobe

The OptiLobe is Alfa Laval’s rotary lobe pump intended for general applications. Available in an optimized range with fewer options, OptiLobe pumps combine cost-effective simplicity with Alfa Laval quality and reliability. OptiLobe pumps feature a paint-free design with front-loading seals and tri-lobe rotors. They are the latest example of Alfa Laval’s leadership in innovative design and advanced manufacturing processes.

| Articlenr. | Description | Stock |

|---|---|---|

|

34247299AL

|

Lobepump OptiLobe

OptiLobe 12 AISI 316L

Acc. spec.

|

|

| Articlenr. | Description | Dimension | Elastomer | Stock |

|---|---|---|---|---|

|

AL9630686639

|

Sparepart Optilobe

Shroud bracket

|

|

|

|

|

34204382AL

|

Lip seal flushed mechanical seal

Optilobe 32-33 Rotary lobe pump

FPM (Viton)

|

|

|

|

|

34204383AL

|

Lip seal flushed mechanical seal

Optilobe 42-43 Rotary lobe pump

FPM (Viton)

|

|

|

|

|

AL9650209001

|

Lip seal flush FPM

OS22/24/26

|

|

|

|

|

34204381AL

|

lip seal flushed mechanical seal

Optilobe 22-23 Rotary lobe pump

FPM (Viton)

|

|

|

|

|

AL9650209101

|

CIRCLIP SEAL FLUSH

OS22/24/26

|

|

|

|

|

AL9650208502

|

O RING FPM

OS22/24/26

|

|

|

|

| Type | Rotary lobe pump |

| Max. temp. C° | 130 gr. C° |

| Flow Range m³/h | 48 m³ / h |

| Max. pressure bar | 8 bar |

| Product wetted parts | Stainless steel 316L |

| Other stainless steel parts | Stainless steel 304 |

| Standard finish | - |

| Standard seal | EPDM |

| Optional | FPM |

| Mechanical seal | Carbon / SS |

| Optional seals | Carbon / Sil. carbide and Sil. Carbide / Sil. Carbide |

| Double shaft seal | Option |

| Flushed shaft seal | Option |

| Other shaft seals | Pack Gland |

| Proces connection | Choice |

| Options | DIN 11851, BS 4825, SMS, IDF, RJT and Tri-Clamp |

| Standards | 3A and EHEDG |