Alfa Laval Unique Basic

Applying the Alfa Laval Unique Basic

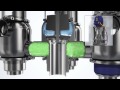

Alfa Laval offers a wide range of sanitary valves fitted with a double seat. The Alfa Laval mixproof valve is characterized by a dual seal which minimizes the risk of undesired mixing of two different liquids. Should a seal fail, then the leaking fluid is discharged via the so-called leak detection and this can be observed visually. The Alfa Laval mixproof valve program is divided into leak valves and double seat valves leak.

Alfa Laval's leak detection valves (SMP-type BC and SMP-BCA) are provided with a pair of seals mounted on a single spindle. The service leakage cavity can be cleaned via a separate connection. In the open position the supply line of the cleaning liquid will be closed automatically by means of built-in shut-off valves when the discharge from the leak detection appears. All mixproof leak detection valves of Alfa Laval has two seals which can move independently. In addition, these valves, switch leak and the leakage cavity remain atmospheric at all times (even during CIP).

Alfa Laval Unique

The Unique mixproof leak detection valves are characterized by a modular structure. Depending on the application, both the lower and upper spindle can be equipped with an independent seat lift, balancing and/or external rinsing. Also, the external flushing of the leakage cavity is possible. The Alfa Laval mixproof valve type SMP-SC is equipped with both a lower and upper seat lift as well as a balancing of the lower spindle. Optionally an external coil connected to the balancing is available.

Alfa Laval also has a double seat leak detection tank bottom valve (Type SMP-TO) in its package, as well as aseptic double seat valve leak detection type AMP. For replacement of the seals on the spindle auxiliary tool is needed. Its use is relatively simple and is clearly illustrated in the detailed instruction manual or on the CD-ROM instruction which come with this tool. All double seat valves are manufactured from 316L stainless steel and fitted with EPDM sealing. Optionally, NBR, HNBR (Unique) or FPM available.

| Articlenr. | Description | Dimensions | Stock |

|---|---|---|---|

|

33138070SSVM

|

Single seat valve SSV

Type 210 (124) 2" EPDM 316L

NO maintainable actuator

|

2" (ø 50,8 mm) |

|

|

33336208AL

|

Double seat valve Unique 316L

Basic 11-90 (24) 1.5" EPDM

|

1,5" (ø 38,1 mm) |

|

|

33336228AL

|

Double seat valve Unique 316L

Basic 11-180 (34) 1.5" EPDM

|

1,5" (ø 38,1 mm) |

|

|

33336230AL

|

Double seat valve Unique 316L

Basic 11-180 (34) 2" EPDM

|

2" (ø 50,8 mm) |

|

|

33336292AL

|

Double seat valve Unique 316L

Basic 12-90 (234) 2.5" EPDM

|

2,5" (ø 63,5 mm) |

|

|

33926230AL

|

Double seat valve Unique 316L

Basic 11-180 (34) 2" EPDM

Tri-clamp connections

Without seat lift

|

2" (ø 50,8 mm) |

|

| Articlenr. | Description | Dimension | Elastomer | Stock |

|---|---|---|---|---|

|

AL9611921773

|

Spare part Alfa Laval valve

service kit NBR unique double

SEAT 51/DN50 PLUG SET-UP 10&11

|

|

|

|

|

33998014AL

|

Maintanance tool

under plug Unique 4"/6"-DN100/150

|

|

|

|

|

AL9611921814

|

Spare part Alfa Laval valve

service kit EPDM unique double

SEAT 38/DN40 PLUG SET-UP 12

|

|

|

|

|

33340019AL

|

Spare part Unique Basic

DN150 FPM (Viton)

|

|

|

|

|

AL9611921767

|

Spare part Alfa Laval valve

service kit EPDM unique double

SEAT 51/DN50 PLUG SET-UP 10&11

|

|

|

|

|

AL9611921818

|

Spare part Alfa Laval valve

service kit EPDM unique double

SEAT 101.6/DN100 PLUG SET-UP 12

|

|

|

|

|

AL9611921697

|

Spare part Alfa Laval valve

service kit EPDM unique double

SEAT 63.5-76/DN65-80 PLUG SET-UP 7

|

|

|

|

|

AL9611921828

|

Spare part Alfa Laval valve

service kit FPM unique double

SEAT 63.5-76/DN65-80 PLUG SET-UP 12

|

|

|

|

|

AL9611921648

|

Spare part Alfa Laval valve

service kit EPDM unique double

SEAT 63.5-76/DN65-80

PLUG SET-UP 5&8

|

|

|

|

|

AL9611921827

|

Spare part Alfa Laval valve

service kit FPM unique double

SEAT 51/DN50 PLUG SET-UP 12

|

|

|

|

|

33300943AL

|

Spare part Unique Mixproof

Valve body DN50/53 11-270

Blasted 316L

|

|

|

|

|

33340015AL

|

Spare part Unique Basic

DN80 FPM (Viton)

|

|

|

|

Material |

|

| Product contact with parts | AISI 316L / 1.4404 |

| ID finish | Standard Ra 1,6 μm, optional 0,8 μm |

| Other stainless steel parts | AISI 304 / 1.4301 |

| Standard seals | EPDM |

| Max. operating pressure | 10 bar |

| Sizes | EN10357-A, EN10357-D (SMS 3008) en Sch.5 |

| Optional seals | NBR, HNBR or FPM |

| Valve | Two – piece stainless steel |

Driving |

|

| Required air pressure | Max. 8 bar |

| Spring closing / spring opened | Spring closed |

| With intergrated lift drive | No |

Operating |

|

| Seal (valve) | Double seal |

| Visual leak detection | Under valve shaft |

| Cleaning leak room | No |

| Cleanable upper valve | No |

| Cleanable under valve | No |

| Yes | |

| Balanced valve | No |

| Leak proof shifting | |

Maintenance |

|

| House connection | Welded or Clamp |

| Revision/disassembly | In line upper demountable |

| Special tool necessary | Yes for the seals |